Custom Down Vest Manufacturer: How to Choose the Right Partner

Introduction — Why Choosing the Right Custom Down Vest Manufacturer Matters

In the fast-paced world of fashion and outdoor apparel, down vests have become a staple for brands looking to deliver lightweight warmth and versatile layering pieces. Whether you run a luxury fashion label, an outdoor performance brand, or a private-label line, choosing the right custom down vest manufacturer can determine the success or failure of your entire collection.

The difference between a successful launch and a disastrous season often comes down to your manufacturer reliability. High-quality down vests demand precision: from the fill type and fill power to the quilting construction, fabric selection, and finishing techniques. Brands that partner with unqualified manufacturers risk receiving inconsistent sizing, late deliveries, or garments plagued with down leakage — all of which can erode customer trust and destroy profit margins.

As a professional custom down jacket and down vest manufacturer, we at Ginwen have seen countless brands struggle with unreliable suppliers before switching to us. That why we created this comprehensive guide — to help you evaluate manufacturers effectively and choose a partner who will elevate your brand rather than hold it back.

Common Pain Points When Sourcing Custom Down Vests

Before exploring how to choose a manufacturer, it’s important to understand the typical challenges that brands face. These pain points highlight what you must avoid:

1. Late Deliveries

Late deliveries can completely derail seasonal launches. Down vests are highly seasonal products, and missing a fall or winter delivery window can result in unsold inventory and financial losses. Many manufacturers overpromise on capacity and fail to deliver bulk orders on time.

2. Inconsistent Sizing and Fit

Sizing inconsistencies are a common issue, especially with manufacturers lacking advanced CAD pattern-making capabilities. Poor grading across sizes leads to customer complaints, high return rates, and reputational damage.

3. Down Leakage and Poor Durability

Down leakage occurs when stitching quality or fabric density is insufficient. It not only ruins the aesthetic but also compromises thermal performance. This often happens when a manufacturer cuts costs on shell fabric or skips proper quilting techniques.

4. Lack of Communication and Transparency

Brands need clear communication about production schedules, sampling feedback, and quality control. Many factories offer little visibility into their workflow, which can create unexpected delays and quality surprises during bulk production.

Key Evaluation Criteria for Selecting a Custom Down Vest Manufacturer

The following evaluation checklist will help you assess any potential custom down vest manufacturer. Each criterion plays a critical role in ensuring you receive premium-quality products on time and at scale.

1. Fill Type & Fill Power

The fill inside your down vest determines warmth, weight, and compressibility. High-end down vests typically use duck or goose down with a fill power rating between 600–900 FP. A reputable manufacturer should offer:

Clear specifications of down type (RDS-certified preferred)

Ability to customize fill power based on climate use

Alternative options like eco-friendly recycled insulation for sustainable collections

At Ginwen, we provide a full range of filling options — from premium high-fill-power duck down to recycled padding — allowing brands to customize thermal performance while meeting sustainability goals.

2. Shell and Lining Fabrics

The outer shell fabric determines durability, while the lining affects comfort and breathability. Choose a manufacturer experienced with high-density nylon or polyester shells that are down-proof, lightweight, and optionally water-repellent, paired with smooth, breathable linings.

Our team at Ginwen carefully inspects all fabrics before cutting. We operate with automated fabric inspection systems and in-house washing lines to ensure fabric stability and minimize shrinkage or distortion in final garments.

3. Quilting / Baffle Construction

Quilting design is crucial to maintaining even down distribution and eliminating cold spots. Manufacturers should offer:

Horizontal, vertical, or body-mapped quilting styles

Advanced baffle wall techniques to prevent down shifting

Heat-sealed or bonded seams for ultra-lightweight designs

At Ginwen, we use CAD-based pattern development and precision quilting machines, enabling brands to achieve innovative silhouettes while maintaining insulation performance.

Workmanship Tolerance & Quality Standards

Even if the materials are excellent, poor workmanship can ruin a garment. A reliable custom down vest manufacturer should demonstrate strict workmanship tolerances — this refers to the allowable deviation in stitching, cutting, and assembly.

Look for factories that:

Maintain ±3mm tolerance on panel cutting

Use automated cutting machines to reduce human error

Implement in-line quality inspections during each sewing stage

Apply reinforced stitching on stress points like armholes, pocket openings, and zipper plackets

At Ginwen, we run a fully automated production line that includes cutting, sewing, printing, and packaging, all supervised by real-time quality monitoring systems. This ensures every vest leaving our factory meets brand-level standards, whether you order a single sample or a 50,000-piece run

Laboratory Testing Capabilities

Before committing to bulk production, it’s essential to validate that your down vests meet safety and performance standards. Professional manufacturers should have access to — or partnerships with — accredited laboratories.

Key lab tests include:

Down fill power and composition tests to verify quality claims

Fabric colorfastness and abrasion resistance tests to ensure durability

Thermal insulation (CLO value) tests to measure warmth

Needle detection and metal contamination checks to meet export compliance

We partner with third-party labs and also conduct internal quality audits at Ginwen. Every production lot is inspected for fill composition, fabric durability, and garment performance to ensure consistency across all units.

Certifications and Compliance Stack

Certifications are strong indicators of a manufacturer’s professionalism, ethics, and operational maturity. When choosing a custom down vest or custom down jacket manufacturer, check that they maintain:

1.ISO 9001 for quality management systems

2.BSCI (Business Social Compliance Initiative) for ethical labor practices

3.RDS (Responsible Down Standard) to guarantee ethical sourcing of down

4.OEKO-TEX or GRS for sustainable materials (if using recycled content)

At Ginwen, we proudly hold ISO 9001 and BSCI certifications, and all our down suppliers are RDS-certified. This compliance stack helps our brand partners ensure their products meet the requirements of top global retailers and eco-conscious consumers.

Minimum Order Quantity (MOQ) Flexibility

MOQ can make or break a project, especially for startups or capsule collections. Many large factories only accept orders of 500–1000 pieces per style, which locks out small brands from developing innovative down vests.

Ginwen is uniquely positioned to support MOQ from just 1 piece. This low barrier enables fashion startups and private labels to create samples, test new silhouettes, and validate market response before scaling up production. Once ready, we can easily scale your order to 500,000 pieces per month thanks to our automated capacity.

Sampling Speed

Speed is critical in the competitive fashion industry. A manufacturer should be able to produce samples quickly without compromising quality. Long sampling timelines often cause brands to miss seasonal buying windows.

At Ginwen, our in-house CAD prototyping team enables us to deliver samples within 7–14 days, including pattern development, material sourcing, and full finishing. This rapid turnaround accelerates your go-to-market process and gives you a competitive edge.

Bulk Production Lead Time

After approving samples, your bulk production schedule determines whether you hit your delivery windows. Typical industry lead times range from 30–60 days, depending on order size and complexity.

Thanks to our automated production systems and real-time bottleneck tracking, Ginwen consistently completes bulk production within 30 days, even for large orders. This makes us an ideal custom down jacket and down vest manufacturer for brands with strict seasonal calendars or retail deadlines.

Logistics and Global Shipping Terms

Lastly, check if the manufacturer has experience in handling global logistics. Many factories focus only on production and lack the ability to manage export documentation or coordinate with freight forwarders, which often causes costly shipping delays.

Ginwen provides end-to-end support, including:

Packing to retailer specifications (polybag, hangtags, barcodes)

Export paperwork preparation (CO, Form A, packing lists, commercial invoices)

Flexible shipping options (FOB, CIF, DDP) to match your needs

This complete service scope ensures your custom down vests are delivered on time, in full, and retail-ready.

Why These Criteria Matter

Choosing a custom down vest manufacturer isn just about price. It about ensuring:

Your product aligns with your brand quality standards

Your supply chain operates on schedule

Your customer experience remains consistent

By evaluating vendors across these ten dimensions — from fill power to certifications, MOQ flexibility, and logistics capability — you can dramatically reduce risk and maximize the return on your investment.

At Ginwen, we built our systems around exactly these principles: ISO-certified production, CAD-based prototyping, automated manufacturing, 500,000 units/month capacity, full private label services, and real-time production tracking. Whether you need one prototype or a global rollout, we have the infrastructure to support your brand growth.

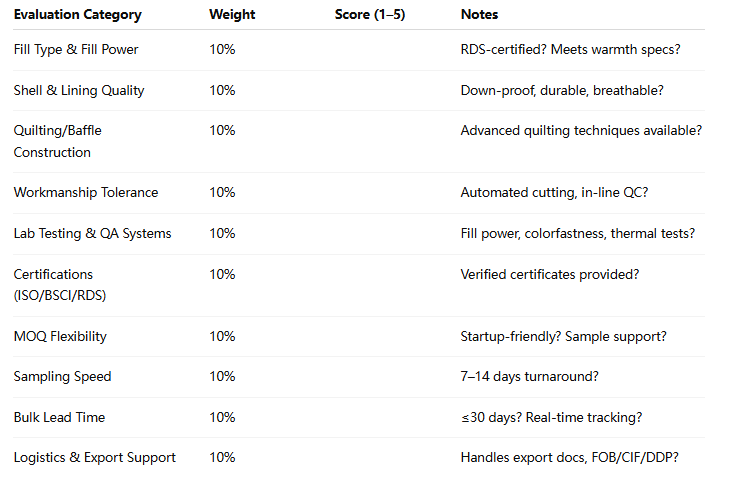

Vendor Scorecard Template — How to Compare Down Vest Manufacturers

After identifying potential partners, you’ll need a structured way to evaluate them. A vendor scorecard helps you objectively compare manufacturers based on the key criteria discussed earlier. Assign a score from 1 (poor) to 5 (excellent) for each category, then calculate the total.

A total score above 85% usually indicates a reliable and professional custom down vest manufacturer. Keep all notes, certificates, and communications in a shared project folder for your team’s reference.

Red Flags When Choosing a Custom Down Vest Manufacturer

Just as important as what to look for is what to avoid. Here are common warning signs that indicate a manufacturer might not be a good long-term partner:

1. Unclear Quoting and Hidden Costs

If a manufacturer avoids providing itemized quotations or frequently changes prices without explanation, it’s a sign of weak financial discipline. This can lead to surprise costs during production.

2. No Quality Certifications

Lack of ISO, BSCI, or RDS certifications suggests that the manufacturer doesn’t follow international standards — putting your brand reputation at risk.

3. Poor Communication and Delayed Responses

Long response times, vague answers, or frequent staff turnover indicate disorganization and can slow down development cycles.

4. Inflexible MOQ or Timelines

Rigid policies on high MOQs and slow sampling show that a manufacturer is not startup-friendly and may not prioritize smaller brands.

5. Outdated Equipment and Facilities

Factories using only manual cutting or basic sewing machines often produce inconsistent sizing and finish. Look for factories with automated CAD cutting, quilting, and real-time QC systems.

Spotting these red flags early can save your brand from wasted time, capital, and reputational damage.

Ginwen – Your Reliable Partner in Custom Down Jackets

At Ginwen, we specialize in custom down jacket and down vest manufacturing for fashion brands, outdoor labels, and private label clients worldwide. With over 20 years of experience in outerwear production, we’ve built a solid track record for quality, speed, and service.

We offer a low MOQ of just 1 piece, making us the perfect partner for startups, sample development, or capsule collections. But we’re equally equipped to handle large orders, with a monthly production capacity of 500,000 units, powered by automated manufacturing lines.

Our factory is ISO 9001 & BSCI certified, ensuring ethical and high-standard production processes. We offer full in-house capabilities — from fabric inspection, washing, CAD prototyping, printing, cutting, and sewing — with real-time tracking to ensure deadlines are met without compromising on quality.

Why Choose Us

✅ ISO 9001 & BSCI certified production systems

✅ MOQ from 1 piece — ideal for startups & capsule collections

✅ 500,000 pieces/month automated capacity

✅ Full in-house facilities: CAD, washing, cutting, printing, QC

✅ Private label expertise: custom logos, labels, trims & packaging

✅ Expert in performance down jackets: reflective panels, eco-padding, water-repellent finishes

✅ Real-time production tracking & bottleneck management

We help transform your design sketches into fully finished down vests — ready to sell in global retail channels. Whether you need high-fill-power down insulation or eco-friendly recycled padding, our CAD development team will guide you from concept to production.

And because we provide samples in 7–14 days and bulk delivery in 30 days, you’ll never miss a seasonal deadline.

If you’re ready to bring your custom down vest ideas to life, contact our team today to request a spec sheet and sample pack

Conclusion — Building Long-Term Success With the Right Partner

Choosing the right custom down vest manufacturer is not just a sourcing decision — it’s a strategic partnership that will impact your brand’s reputation, operational efficiency, and profitability. Brands that rush this decision often face production delays, inconsistent sizing, and costly quality issues.

By contrast, brands that take the time to evaluate manufacturers based on technical expertise, quality systems, certifications, MOQ flexibility, and delivery performance are the ones that build reliable supply chains and scale globally.

As we’ve covered, your ideal manufacturing partner should offer:

Strong material knowledge (high fill power, down-proof shells, breathable linings)

Advanced technology (CAD patterning, automated cutting and quilting)

Certified quality systems (ISO 9001, BSCI, RDS)

Low MOQs to support sampling and small-batch launches

Rapid turnaround (7–14 days samples, 30 days bulk)

Global logistics capability (FOB, CIF, DDP terms)

At Ginwen, this is exactly what we deliver. Our mission is to give brands of all sizes — from emerging designers to established global retailers — the ability to produce high-performance down vests and custom down jackets at world-class standards.

Why This Matters for Your Brand

Global apparel markets move fast. Trends change quickly, and seasonal buying windows are tight. Missing deadlines can mean missing entire revenue cycles. Partnering with a manufacturer that offers speed, scalability, and reliability is essential to staying competitive.

When you choose Ginwen as your custom down vest manufacturer, you gain:

A partner who understands fashion timelines and operates at retail speed

A team that integrates design development, production, and quality control under one roof

A factory that scales with you — from 1-piece samples to 500,000-piece bulk orders

Transparent communication and real-time progress tracking, so you always know where your order stands

We don’t just produce garments; we build supply chain confidence for our clients.

Call to Action — Start Your Down Vest Project Today

If you’re ready to transform your concept into a market-ready product, Ginwen is here to support you at every step.

Located in China

Whether you need a single prototype to test a new silhouette or a full production run for a global retail launch, we can make it happen — samples in 7–14 days, bulk delivery in 30 days, all backed by ISO 9001 & BSCI-certified systems.

Don’t let production headaches hold your brand back.

Request a spec sheet and sample pack today — and launch your custom down vest collection with confidence.