How to Choose High-Performance Materials for Custom Waterproof Jackets

Introduction: Why Material Selection Defines Jacket Performance

When it comes to custom waterproof jackets, material choice is everything. While style and fit attract customers, it the fabric performance that determines whether a jacket truly protects against the elements. For fashion brands and outdoor retailers, investing in the right high-performance materials not only improves functionality but also strengthens brand reputation.

In today competitive market, buyers expect waterproof jackets that are lightweight, breathable, durable, and stylish. Selecting the right fabrics, membranes, and insulation — whether synthetic or down filling for insulated waterproof options — ensures that your products stand out.

In this article, we’ll explore the key materials used in custom waterproof jackets, how to evaluate their performance, and how we at Ginwen help brands worldwide select and produce jackets that meet the highest standards.

Understanding the Science of Waterproofing

Not all fabrics labeled “waterproof” perform equally. A high-quality custom waterproof jacket requires materials that combine water resistance, breathability, and durability.

Key concepts to understand:

Hydrostatic Head (HH): Measured in millimeters, it shows how much water pressure a fabric can withstand before leaking. Jackets with 10,000 mm+ HH are considered high-performance.

Breathability (MVTR): Indicates how well moisture vapor passes through the fabric, preventing sweat build-up.

Seam Sealing: Even the best fabric leaks if seams aren sealed with waterproof tape or welding.

Durability: Abrasion resistance and longevity matter for jackets used in outdoor sports and urban wear alike.

At Ginwen, we work with clients to balance these metrics, ensuring their custom waterproof jackets perform across environments, from city streets to mountain trails.

Popular Fabrics Used in Custom Waterproof Jackets

1. Nylon with PU or TPU Coatings

Lightweight, cost-effective, and versatile. PU (polyurethane) coatings enhance waterproofness, while TPU adds elasticity.

2. Polyester with DWR (Durable Water Repellent)

Common in urban waterproof jackets. Environmentally friendly options include recycled polyester with PFC-free coatings.

3. Laminated Membranes (e.g., Gore-Tex®, eVent®)

Premium, breathable, and extremely durable. Ideal for high-performance outdoor gear.

4. Softshell Fabrics

Offer stretch and comfort with moderate water resistance, often paired with fleece linings.

5. Insulated Waterproof Fabrics

For cold climates, outer shells are paired with synthetic insulation or down filling. This combination provides warmth while maintaining waterproof performance.

Each material has trade-offs. Nylon offers strength, polyester offers eco-options, and membranes offer top-tier protection. The choice depends on your brand market positioning.

Why Insulation and Down Filling Are Important in Waterproof Jackets

For winter-ready custom waterproof jackets, adding insulation is critical. This is where down filling comes into play:

1.Down filling provides superior warmth-to-weight ratio and compressibility.

2.Jackets with RDS-certified down filling combine ethical sourcing with premium performance.

3.Synthetic fills work in damp environments but are heavier and less breathable.

At Ginwen, we guide brands on whether to use down or synthetic insulation in their waterproof jackets OEM & ODM Service. By testing fill power, loft, and moisture resistance, we ensure warmth without compromising waterproof performance.

Ginwen: Your Reliable Partner for Custom Waterproof Jackets

outdoor retailers. Here what makes us stand out:

ISO 9001 & BSCI certified systems for reliability and ethics

In-house CAD prototyping team for accurate fit and design translation

500,000 pcs/month capacity with automated production lines

End-to-end services — cutting, sewing, seam-sealing, and private label customization

Real-time QC monitoring to ensure waterproof integrity and insulation quality

Low MOQ from 1 piece, ideal for startups, sample runs, or capsule collections

Fast delivery: 7–14 days for samples, 30 days for bulk

Because we manage every process in-house, we can guarantee that your custom waterproof jackets meet international standards and consumer expectations.

How to Choose High-Performance Materials for Custom Waterproof Jackets

This section covers:

Advanced coatings & eco-finishes

Waterproof testing methods

Common mistakes brands make when sourcing materials

A Ginwen client case study

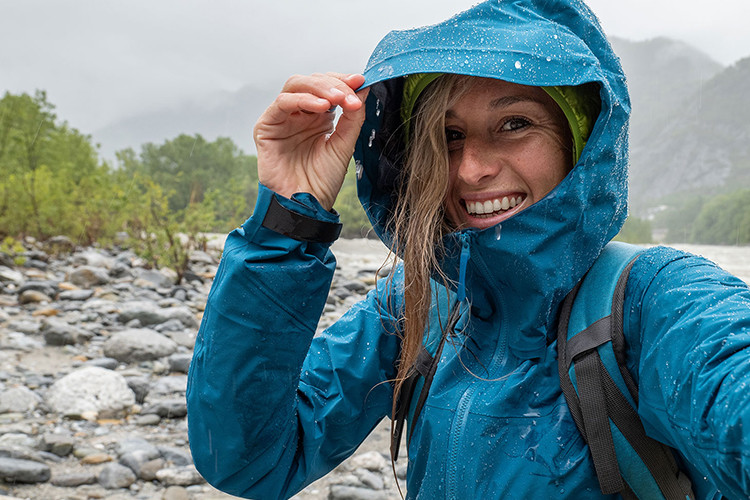

Natural use of Custom Waterproof Jackets and down filling

Advanced Coatings and Eco-Friendly Finishes

The performance of custom waterproof jackets often depends not only on the base fabric but also on its surface treatment.

Durable Water Repellent (DWR) Coatings

Applied to fabric surfaces to make water bead and roll off.

Traditionally PFC-based, but many brands are now shifting to PFC-free DWR for sustainability.

PU and TPU Coatings

Polyurethane (PU) and Thermoplastic Polyurethane (TPU) enhance water resistance.

PU is cost-effective, while TPU adds elasticity and durability.

Eco-Friendly Laminates

Brands increasingly demand bio-based membranes or recycled polyester with eco-finishes.

These reduce environmental impact while maintaining waterproof standards.

At Ginwen, we offer both traditional and eco-friendly finishing options, ensuring your custom waterproof jackets align with evolving consumer expectations for performance and responsibility.

Testing Methods for Waterproof Jacket Fabrics

High-performance custom waterproof jackets must pass rigorous testing to validate durability and protection.

Key Tests Include:

Hydrostatic Head Test

Measures how much water pressure fabric withstands before leakage. A rating of 10,000–20,000 mm HH is excellent for outdoor wear.

Breathability (MVTR Test)

Verifies how much water vapor passes through fabric, keeping the wearer dry and comfortable.

Spray Rating Test

Evaluates how well fabric resists surface wetting when exposed to simulated rainfall.

Seam Leakage Test

Ensures taped or welded seams remain waterproof under stress.

Down Filling Moisture Retention

For insulated waterproof jackets, we test down filling loft and moisture performance after simulated rain exposure.

By combining these methods, we ensure that every jacket meets both lab standards and real-world performance needs.

Common Mistakes Brands Make When Choosing Materials

Brands often underestimate the complexity of selecting fabrics and insulation for custom waterproof jackets. Here are the most frequent errors:

1.Confusing Water-Resistant with Waterproof

Low-cost fabrics labeled “water-resistant” often fail under heavy rain. Waterproof fabrics must pass hydrostatic head standards.

2.Ignoring Breathability

Jackets that trap sweat quickly lose consumer appeal. Always balance waterproofness with breathability.

3.Overlooking Seam Sealing

Even with premium fabric, unsealed seams cause leakage. Proper seam taping or welding is essential.

4.Not Testing Insulation with Waterproof Shells

Brands adding down filling sometimes fail to test loft retention in damp conditions, leading to poor performance.

5.Chasing the Lowest Price

Cheap fabrics and coatings degrade quickly, causing consumer complaints and high return rates.

At Ginwen, we help clients avoid these pitfalls by guiding material selection, testing, and production — ensuring long-lasting, high-performance custom waterproof jackets.

Case Study: Helping a Brand Launch a Sustainable Waterproof Jacket Line

One of our European outdoor clients wanted to launch a line of custom waterproof jackets made with sustainable fabrics. Their goals were:

Use recycled polyester with PFC-free DWR

Add down filling for warmth in winter jackets

Achieve short sampling timelines for seasonal launches

Maintain competitive pricing without compromising quality

Our Solution:

Within 10 days, our CAD team developed prototypes using eco-certified materials.

We sourced RDS-certified down filling for insulated options.

Our real-time QC monitoring ensured consistent seam sealing and waterproof ratings.

Bulk production was completed in 30 days, allowing on-time delivery for retail rollout.

The Result:

Jackets sold out in their first season due to strong consumer response.

Retailers praised the balance of sustainability, warmth, and durability.

This case highlights why working with an experienced bomber and waterproof jacket manufacturer like Ginwen provides both speed and reliability.

Why Brands Choose Ginwen for Custom Waterproof Jackets

At Ginwen, we specialize in turning material challenges into market-ready solutions. Our strengths include:

ISO 9001 & BSCI certified systems for compliance and quality

500,000 pcs/month capacity with automated production

CAD prototyping team for precise fit and design support

Full customization: waterproof shells, insulation (synthetic or down filling), trims, packaging

Low MOQ from 1 piece — ideal for samples and capsule launches

Fast lead times: 7–14 days for samples, 30 days for bulk orders

We help brands choose fabrics and coatings that align with their identity, whether it’s urban fashion, outdoor performance, or sustainable innovation.

How to Choose High-Performance Materials for Custom Waterproof Jackets

This part covers:

A practical checklist for brands choosing materials

Step-by-step guide to working with Ginwen

Why Ginwen is the ideal partner

SEO-focused conclusion & CTA

Optimized meta description & 6 SEO keywords

Checklist: How to Select Materials for Custom Waterproof Jackets

Choosing the right material is critical for producing custom waterproof jackets that perform in real conditions. Here’s a checklist to guide fashion brands and outdoor labels:

Waterproof Rating

Verify hydrostatic head levels (10,000–20,000 mm for outdoor use).

Breathability

Ensure the fabric allows vapor release, measured through MVTR testing.

Coating or Membrane

PU/TPU coatings for affordability; laminated membranes for premium performance.

Eco Credentials

Consider PFC-free DWR coatings and recycled polyester to align with sustainability trends.

Seam Sealing Compatibility

Fabrics must be tested for effective tape sealing or welding.

Insulation

For winter jackets, test the interaction between waterproof shells and down filling or synthetic fills.

Durability

Check abrasion resistance, color fastness, and wash durability.

Supplier Capability

Partner with a manufacturer who manages CAD, QC, and automated production in-house.

By following this checklist, brands can ensure their custom waterproof jackets deliver on both functionality and consumer expectations.

Step-by-Step: How to Start With Ginwen

At Ginwen, we’ve designed a clear and efficient process to help brands launch custom waterproof jackets:

Step 1 — Share Your Concept

Send us your tech packs, sketches, or sample garments. We digitize your designs with our CAD team for precision.

Step 2 — Material Consultation

We recommend fabrics, coatings, and insulation options, including down filling for cold-weather jackets.

Step 3 — Prototype Development (7–14 Days)

We build samples with seam sealing and branding elements so you can test fit and performance quickly.

Step 4 — Bulk Production (30 Days)

Once approved, your design moves to automated production lines: fabric inspection, washing, CAD cutting, seam sealing, sewing, printing, packaging.

Step 5 — Real-Time QC

Our system continuously monitors seam sealing, down filling distribution, and waterproof integrity.

Step 6 — Final Inspection & Delivery

We complete AQL inspections, apply your private label trims and packaging, and ship globally via FOB, CIF, or DDP.

This process ensures that every Ginwen project delivers speed, quality, and transparency.

Why Choose Ginwen for Custom Waterproof Jackets

At Ginwen, we combine decades of manufacturing expertise with modern technology to create custom waterproof jackets that exceed expectations.

Our Strengths:

ISO 9001 & BSCI certified manufacturing systems

In-house CAD development & prototyping

500,000 pcs/month capacity for both small and large orders

End-to-end automated production: inspection, washing, CAD cutting, seam sealing, sewing, printing, packaging

Private label customization: logos, labels, trims, packaging

Real-time QC monitoring for consistent quality

MOQ from 1 piece — supporting startups, samples, and capsule runs

Fast lead times: 7–14 days for samples, 30 days for bulk

We don just produce jackets; we help brands build collections that perform, sell, and scale.

Conclusion: Build Your Next Collection With Confidence

The choice of materials defines the success of your custom waterproof jackets. From waterproof membranes and coatings to insulation with down filling, every decision impacts performance, durability, and consumer satisfaction.

By partnering with a trusted factory like Ginwen, you gain access to:

Certified systems

Advanced prototyping

Large-scale capacity

Private label flexibility

Low MOQ and fast turnaround

📩 Ready to start your project?

Let build custom waterproof jackets that meet global market demands.

🔗 Contact Us.