How to Find the Reliable Bomber Jacket Manufacturer for Your Brand in

Introduction

When you are building or growing a fashion brand, choosing the right Bomber Jacket Manufacturer is one of the most critical decisions you’ll make. A misstep at this stage may lead to production delays, quality problems, or even damage to your brand reputation. Conversely, a reliable Bomber Jacket Manufacturer becomes a strategic partner: consistent quality, dependable delivery, and scalability all contribute to your brand success.

In this guide, I’ll walk you through how to find a reliable Bomber Jacket Manufacturer for your brand, step by step. Along the way, I’ll introduce Ginwen — my company — and explain why we believe we are among the best choices for your bomber jacket production. You’ll see how we meet the critical criteria for a top-tier manufacturing partner, and you can benchmark other manufacturers against that standard.

Why Selecting a Reliable Bomber Jacket Manufacturer Is Essential

1.1 Consistency in Quality

Your customers expect that each bomber jacket you deliver — regardless of season or batch — maintains the same standard. A strong Bomber Jacket Manufacturer uses standardized procedures, trained staff, and quality control checks at every stage (material inspection, midline checks, final inspection). Without consistency, returns, complaints, and reputation damage can accumulate quickly.

1.2 On-Time Delivery & Supply Chain Reliability

Fashion is seasonal: missing deadlines means missing shelf space or sales windows. A dependable manufacturer can adhere to lead times, handle bottlenecks, and offer buffer strategies. Only a true reliable Bomber Jacket Manufacturer gives you confidence in delivery schedules.

1.3 Scalability & Growth Support

Your first order may be modest, but if your brand succeeds, you’ll want to scale quickly. A manufacturer that can go from 100 pieces to tens of thousands without breakdowns is ideal — that’s what separates casual factories from strategic partners.

1.4 Compliance, Certifications & Ethical Operations

In modern markets, brands must demonstrate ethical sourcing, labor standards, and quality assurance. Factories holding recognized certifications (e.g. ISO, social audits) reduce your risk and elevate your brand image. A well-certified Bomber Jacket Manufacturer is an asset, not just a vendor.

1.5 Communication, Transparency & Trust

Even the best factory fails if communication is poor. You need regular updates, transparency about challenges, and a team that treats your brand as a stakeholder. In short: you want to work not just with a factory but with a trusted partner.

Introducing Ginwen — My Company & Why We Are a Trusted Bomber Jacket Manufacturer

Allow me to introduce us in first person: I am part of Ginwen, a professional apparel manufacturer specializing in outerwear and jackets. When I say “we,” I mean the entire team at Ginwen — from design to production to quality control — committed to making your vision a high-quality reality.

Here how we stand out as your future Bomber Jacket Manufacturer:

ISO 9001 & BSCI Certified Manufacturing Systems

We maintain robust quality systems and social compliance standards. These certifications are not for show — they guide how we manage procedures, worker welfare, defects, and continuous improvement.

Strong In-House Team for CAD Development & Prototyping

Our internal CAD engineers and sample workshop allow us to convert your sketches or tech packs into precise prototypes and fit samples, minimizing errors and speeding iteration.

High Manufacturing Capacity

We are capable of producing up to 500,000 pieces per month. From fabric inspection, washing, cutting, printing to packaging, many of our processes are automated or semi-automated to ensure consistency and reduce errors.

Full Scope of Services

We don’t just sew garments. We offer cutting, sewing, finishing, trimming, packaging, and full private label / OEM & ODM services. We take your brand’s design and transform it into retail-ready bomber jackets. (See our OEM & ODM Service page.)

Quality Management & Real-Time Monitoring

In our workshops, we implement real-time progress tracking, bottleneck detection, and multi-stage inspections. This means if a problem arises mid-run, we catch it swiftly — before it becomes a large-scale defect.

We understand brands’ time constraints, so we commit to sample delivery in 7-14 days and bulk production in 30 days. For many brands, starting with 100 pieces is ideal — and that is exactly our minimum order quantity (MOQ = 100 pieces).

You can explore our Custom Bomber Jacket collection here:

If you’re curious about our OEM & ODM capabilities, check:

To reach out and discuss your project, use:

What This Guide Will Cover

In the following sections, we will:

Detail the key criteria you should use to evaluate any Bomber Jacket Manufacturer

Provide a step-by-step vetting process to filter and select reliable candidates

Show how we (Ginwen) perform against each benchmark

Highlight common pitfalls and how to avoid them

Offer a final checklist you can use when negotiating or onboarding

Provide a persuasive call to action for you to consider Ginwen as your long-term partner

By the end, you will be able to assess any Bomber Jacket Manufacturer you come across—compare them against a high standard—and decide with confidence.

Key Criteria to Evaluate a Bomber Jacket Manufacturer

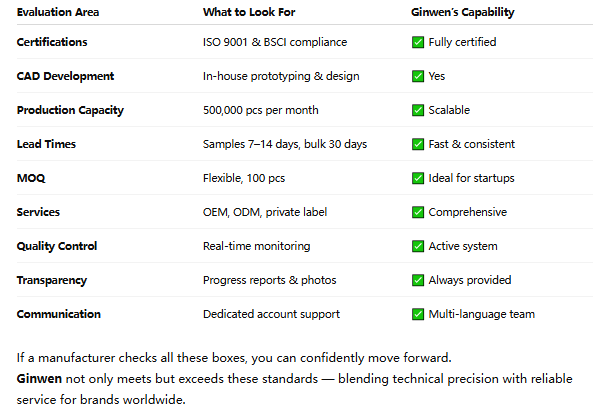

Finding a reliable Bomber Jacket Manufacturer involves more than checking prices or MOQs. You must evaluate their quality systems, technical expertise, scalability, and communication. The following criteria will help you assess any factory — and I’ll explain how we at Ginwen meet each of them.

1. Certifications & Ethical Compliance

Always start by verifying whether a manufacturer follows internationally recognized standards. A certified Bomber Jacket Manufacturer operates under quality-management frameworks that guarantee consistency, traceability, and ethical conduct.

At Ginwen, we are proud to hold ISO 9001 & BSCI certified manufacturing systems.

ISO 9001 ensures every production stage — from fabric inspection to packing — follows documented quality procedures.

BSCI reflects our commitment to ethical labor and responsible sourcing, a crucial factor for fashion brands selling in Europe or North America.

2. In-House Design & CAD Capabilities

2. In-House Design & CAD Capabilities

The ability to translate your creative idea into a precise, reproducible pattern is what differentiates a true Bomber Jacket Manufacturer from a sewing subcontractor.

Our in-house team for CAD development and prototyping allows us to create and adjust digital patterns quickly. We can import your tech packs, simulate garment fit, and correct measurements before cutting the first fabric. This saves both time and money.

When you collaborate with us, we act as your technical partner, not just a production unit. This capability is particularly valuable for OEM Bomber Jacket and Private Label Bomber Jacket projects requiring customized silhouettes and details.

3. Manufacturing Capacity & Automation

A dependable factory must handle both small and large orders without compromising quality.

At Ginwen, our monthly production capacity reaches 500,000 pieces.

We’ve invested in automation across critical steps: fabric inspection, washing, cutting, printing, and packaging. This automation minimizes human error and maintains uniform results across batches.

Such scale means we can deliver small brand orders (100 pcs MOQ) and large retailer programs with equal efficiency. You can start with a sample run and grow into larger volumes confidently — your factory won’t need to change as you scale.

4. Scope of Services — From Cutting to Private Label

coordinate multiple vendors for fabric sourcing, cutting, printing, and labeling.

At Ginwen, our scope of services includes:

Cutting and sewing services for OEM clients

In-house washing and printing departments

Logo, label, and packaging customization for Private Label Bomber Jacket production

Finishing and QC before shipment

Our OEM & ODM services allow you to develop original designs or customize existing styles. Visit our OEM & ODM Service page to see how we turn concepts into market-ready collections.

5. Quality Management & Real-Time Monitoring

A professional factory never leaves quality to chance. Our quality management system monitors every stage of production through real-time dashboards that track progress and flag bottlenecks immediately.

We perform three main inspection points:

Pre-production (material and trim check)

In-line (mid-process inspection)

Final QC (visual and measurement check before packing)

This rigorous approach ensures that each bomber jacket meets our standards before it leaves the factory.

6. Lead Times & Efficiency

Time-to-market defines competitiveness. We deliver samples within 7–14 days and bulk orders within 30 days. Our automated systems and real-time coordination between departments allow us to achieve this without compromising quality.

If you want to see style options we’ve already developed, browse our Custom Bomber Jacket Collection. We update this range seasonally to show the latest fabric and design innovations.

7. MOQ Flexibility & Transparent Pricing

Startups often face the challenge of high minimum order requirements. Our MOQ of 100 pieces lets emerging brands test new styles and markets at manageable cost. We maintain transparent quotes covering fabric, labor, and accessories — no hidden charges or unexpected fees.

8. Communication & Client Support

An excellent Bomber Jacket Manufacturer keeps clients updated at every stage. Our team communicates proactively, sharing photos, production reports, and inspection summaries throughout your order. We also encourage third-party inspections or virtual factory tours for full transparency.

By evaluating manufacturers using these criteria — and by seeing how Ginwen performs in each category — you can confidently identify a reliable Bomber Jacket Manufacturer for your brand. Next, let’s move to Part 3, where we outline a step-by-step process for vetting and selecting your ideal partner.

Step-by-Step Process to Select Your Bomber Jacket Manufacturer

Finding a reliable Bomber Jacket Manufacturer isn’t only about who can make jackets — it’s about who can understand, communicate, and grow with your brand. Below is a proven seven-step process you can follow to identify and evaluate potential manufacturing partners effectively.

Step 1:Build a Shortlist of Manufacturers

Start by collecting a list of potential factories that specifically specialize in bomber jackets or outerwear. Search for keywords like “Bomber Jacket Manufacturer,” “Custom Bomber Jacket Manufacturer,” or “OEM Bomber Jacket Supplier.”

Look for manufacturers that:

Showcase real bomber jacket samples on their website

Have verified business licenses

Offer OEM/ODM customization services

Clearly list materials, capacity, or certifications

A small shortlist of 5–10 candidates gives you enough diversity to compare without being overwhelmed.

Step 2: Verify Their Credentials

Step 2: Verify Their Credentials

Once you have a shortlist, it’s time to check legitimacy. Ask each Bomber Jacket Manufacturer for:

Factory registration documents or business license

ISO 9001 & BSCI certificates

Factory tour photos or videos

List of main export markets or partner brands

A manufacturer unwilling to share such documents is usually not transparent. At Ginwen, we provide digital copies of our certifications, photos of production lines, and even virtual video tours upon request. Transparency is key to trust.

Step 3: Request Product Samples

The best way to assess a Bomber Jacket factory is to see their work firsthand. Request a custom sample based on your design or fabric selection.

We at Ginwen offer:

Sample lead time: 7–14 days

Customizable details: zipper types, lining, quilting, print, or embroidery

Digital sample updates: we send progress photos for your confirmation before shipment

When you receive samples from multiple manufacturers, evaluate:

Stitching neatness

Fabric quality

Trim alignment

Comfort and fit

Finishing precision

Keep notes for each sample so you can compare objectively.

Step 4: Evaluate Communication and Responsiveness

Strong communication is a sign of professionalism. A reliable Bomber Jacket Manufacturer should respond quickly, provide clear answers, and anticipate questions before you ask them.

During your first few exchanges, note:

How quickly they reply

Whether their responses are detailed or generic

If they understand your brand requirements

How they handle technical details (e.g., sizing charts, measurements, trims)

At Ginwen, we assign a dedicated account manager to every client. This ensures that your questions, updates, and decisions move swiftly and nothing gets lost between departments.

Step 5: Review Production Facilities

If possible, visit the factory in person. If not, request a live video tour. Look for:

Modern sewing machines and cutting equipment

Organized production lines

Proper lighting and cleanliness

Quality control checkpoints

Safe and ethical working conditions

We at Ginwen welcome client visits and third-party inspections. Our facilities operate under ISO 9001 & BSCI-certified systems, ensuring ethical production and traceability at every stage.

Step 6: Negotiate Terms, MOQ, and Pricing

Once you’ve confirmed quality and credibility, discuss order terms. A trustworthy Bomber Jacket Manufacturer should provide transparent pricing and flexible MOQ.

We offer detailed quotations including:

Our MOQ is 100 pieces, allowing startups or small brands to launch efficiently.

We offer detailed quotations including:

Fabric and trim costs

Labor and processing fees

Printing, labeling, and packaging costs

Optional add-ons for private label customization

Never hesitate to ask for a complete cost breakdown — reliable factories like Ginwen welcome such transparency.

Step 7: Place a Trial Order & Evaluate Results

Before committing large-scale, run a trial order. This phase helps you confirm whether the factory can maintain consistent quality, timelines, and communication at production scale.

During your trial order evaluation, focus on:

On-time delivery (did they meet the deadline?)

Quality consistency (are all jackets identical to the approved sample?)

Packaging and labeling accuracy

Responsiveness during production

If everything aligns, you’ve found your long-term partner. If not, analyze what went wrong before scaling further.

Bonus Tip: Keep a Long-Term Perspective

Building a sustainable partnership with your Bomber Jacket Manufacturer can save you years of frustration. A good manufacturer learns your brand’s standards, anticipates seasonal changes, and even suggests improvements.

At Ginwen, many of our clients have worked with us for over a decade. We’ve grown together — from small 100-piece test orders to 10,000-piece seasonal programs — because we always put reliability, quality, and open communication first.

Why Choose Ginwen as Your Bomber Jacket Manufacturer

When searching for the ideal Bomber Jacket Manufacturer, you want more than a supplier — you want a long-term production partner who shares your commitment to quality, innovation, and timely delivery. This is where Ginwen stands apart.

At Ginwen, we don’t just manufacture; we collaborate, innovate, and deliver value to fashion brands worldwide. Below, I’ll explain why our brand has become a trusted partner for many private labels, startups, and established fashion houses.

1. Certified Quality and Social Responsibility

Our factory operates under ISO 9001 & BSCI certified manufacturing systems, ensuring both product quality and ethical compliance. These certifications prove that we follow global standards for process control, documentation, and employee welfare.

Many brands today are under pressure to ensure their supply chains meet sustainability and ethical requirements. By working with Ginwen, you can confidently present your products knowing they come from a responsible Bomber Jacket Manufacturer.

2. Advanced In-House CAD Development and Prototyping

2. Advanced In-House CAD Development and Prototyping

Unlike many factories that outsource design work, we have a strong in-house team for CAD development and prototyping. Our pattern engineers convert your creative sketches into production-ready technical files.

This capability allows us to:

Create accurate digital patterns for different sizes and fits

Adjust style details quickly

Provide 3D sample previews before cutting

Shorten sampling cycles to 7–14 days

With our in-house sample room and CAD facilities, your design is protected and executed efficiently. This makes us a perfect partner for OEM Bomber Jacket and Private Label Bomber Jacket programs that demand speed and confidentiality.

3. Massive Monthly Capacity with Automated Efficiency

Capacity matters when your business grows. Ginwen monthly production capacity of 500,000 pieces ensures we can handle both small trial runs and large commercial orders without delays.

Our automated production system includes:

Fabric inspection machines that detect defects early

Automatic washing and drying lines

Laser cutting and digital printing units

Seam sealing, embroidery, and packing departments

By combining automation with skilled craftsmanship, we maintain speed, precision, and flexibility. This means your brand will never face missed deadlines or inconsistent quality.

4. End-to-End OEM & ODM Manufacturing Services

Our scope of services goes beyond traditional cut-and-sew. Ginwen provides:

Fabric sourcing and dyeing support

Pattern grading and marker making

Cutting, sewing, printing, and embroidery

Finishing, pressing, and packaging

Private label and custom branding

If you are building your own brand, our OEM & ODM Service can transform your ideas into market-ready collections. You can explore our full service offering here:

For brands ready to explore designs, view our latest Custom Bomber Jacket Collection:

5. Real-Time Quality Monitoring and Transparent Process

We believe in transparency. From the moment we receive your order, we track every stage of production — cutting, sewing, finishing, and packaging — in real time. Our QC team monitors progress using digital dashboards to identify any bottlenecks or defects early.

Our clients receive photo updates, reports, and shipment confirmations to ensure everything stays on schedule. You’ll always know where your order stands — no surprises, no delays.

6. Fast Lead Time & Flexible MOQ

In fashion, timing is everything. We offer:

Sample delivery: 7–14 days

Bulk delivery: 30 days

Minimum Order Quantity (MOQ): 100 pieces

This flexibility allows emerging designers to test new collections and established brands to scale up quickly. Our efficient processes ensure your bomber jackets are ready when your market is.

7. Partnership and After-Sales Support

What sets Ginwen apart from other Bomber Jacket Manufacturers is our focus on relationships. We view each client as a long-term partner. Our after-sales team remains available for feedback, adjustments, and re-orders.

We also provide design suggestions based on market trends and fabric innovations, helping brands evolve with each season.

For inquiries or custom quotes, feel free to connect with us directly:

Tips, Common Mistakes & Final Checklist Before Partnering with a Bomber Jacket Manufacturer

By now, you understand how to identify a reliable Bomber Jacket Manufacturer, evaluate their systems, and recognize why Ginwen stands out.

In this final section, let’s summarize the practical tips, common pitfalls, and a final checklist that will help you make confident, informed manufacturing decisions.

Pro Tips for Working Effectively with a Manufacturer

Start with Detailed Tech Packs

The clearer your specifications — fabric weight, lining, color, trims, and sizing — the fewer revisions you’ll face. A professional Bomber Jacket Manufacturer appreciates detailed instructions because it ensures accurate production.

Request Pre-Production Samples (PPS)

After approving your first prototype, ask for a pre-production sample from the bulk line. This helps you confirm quality consistency before full-scale manufacturing begins.

Maintain Regular Communication

Schedule weekly updates and photo reports. This habit ensures you spot potential issues early and keeps everyone accountable.

Evaluate Fabric & Trim Swatches Early

Fabrics can vary in texture and shade. Reviewing them early helps avoid disappointment or mismatches during production.

Plan Ahead for Logistics

Coordinate your shipping or forwarding agents early. Reliable factories like Ginwen can assist with export documentation and packing standards to streamline this step.

Protect Your Intellectual Property

Always work with ethical factories. At Ginwen, we treat client designs as confidential and never share them externally — an essential value for Private Label Bomber Jacket clients.

Start Small, Then Scale Up

Begin with a 100-piece trial order. Once satisfied with quality and workflow, expand into larger orders confidently.

Common Mistakes to Avoid When Choosing a Bomber Jacket Factory

Even experienced buyers can make missteps. Avoid these pitfalls when selecting your next Bomber Jacket Manufacturer:

Choosing solely by price — Cheaper isn’t better. It often means inferior materials, outdated equipment, or poor worker conditions.

Ignoring certifications — A non-compliant factory risks shipment seizures, brand audits, or consumer backlash.

Skipping samples — Jumping straight to bulk without testing samples is the fastest way to lose money and damage brand trust.

Weak communication — If the factory takes days to reply during negotiation, imagine how they’ll handle production issues later.

No clear contract — Always have written agreements covering specifications, timelines, quality standards, and penalties.

Overlooking lead times — Rushing production often results in defects or missed deadlines. Always plan ahead.

At Ginwen, our workflow and transparent communication are designed specifically to prevent these common mistakes. We send weekly updates, detailed reports, and encourage direct contact through your dedicated project manager.

Final Checklist: How to Confirm You’ve Found the Right Partner

Why Partnering with Ginwen Brings Long-Term Value

When you collaborate with Ginwen, you gain:

20+ years of experience in outerwear manufacturing

ISO & BSCI certifications ensuring global compliance

Strong CAD and sample development to refine your designs

Automated production for accuracy & efficiency

500,000 monthly capacity to support scaling brands

7–14 day sample turnaround & 30-day production

MOQ starting from just 100 pieces

Full private label & OEM support

Whether you are building your first bomber jacket collection or expanding a global retail brand, we have the infrastructure and expertise to make it happen.

Call to Action — Let’s Create Together

Explore our Custom Bomber Jacket Collection → Custom-Bomber-Jacket.

Learn about our full OEM & ODM capabilities → OEM-ODM-Service.

Contact our team today for a quote or consultation → contact-us.

At Ginwen, we don’t just manufacture — we empower fashion brands to succeed.

Let’s build your next line of bomber jackets with quality, precision, and confidence.