OEM vs Private Label vs White Label Puffer Vest Manufacturer

Introduction: Why the Right Puffer Vest Manufacturer Matters

In today’s fashion supply chain, choosing the right Puffer Vest Manufacturer determines how efficiently a brand can bring ideas to market. Whether you’re launching a new outerwear line, expanding your wholesale portfolio, or seeking reliable private label production, understanding different manufacturing models — OEM, Private Label, and White Label — is essential.

Each model offers distinct advantages depending on your goals, budget, and creative control. But without understanding their differences, brands risk overpaying, missing deadlines, or producing garments that don’t align with their market positioning.

At Ginwen, we’ve spent over 20 years manufacturing puffer jackets, down vests, and technical outerwear for global brands. As an experienced Puffer Vest Manufacturer, we support all three cooperation models — OEM, Private Label, and White Label — helping clients choose the best path based on their strategy and scale.

The Rising Demand for Custom Puffer Vests

The global puffer vest market is thriving due to its versatility — lightweight, warm, and suitable for both outdoor and urban wear. From minimalist streetwear to high-performance winter gear, brands are increasingly turning to specialized Puffer Vest Manufacturers who can provide not only production but also design insight and fabric innovation.

Fashion trends now prioritize:

Recycled and sustainable insulation materials

Technical nylon or polyester shells

3D CAD patterning for perfect fit

Private label customization (logos, trims, labels, packaging)

At Ginwen, we combine all these capabilities under one roof. Our factory is ISO 9001 & BSCI certified, equipped with automatic sewing and quilting lines, and capable of producing 500,000 pieces monthly.

We also offer Custom Puffer Vests for brands that want to stand out — from high-gloss lightweight nylon styles to matte-finished urban silhouettes.

Explore more styles:

OEM, Private Label, and White Label — What Do They Mean?

Before selecting a Puffer Vest Manufacturer, it crucial to understand what each model entails:

OEM (Original Equipment Manufacturer) – You provide the design, and the factory executes the full production with your specifications. Perfect for brands with design teams that want technical precision.

Private Label – The manufacturer produces products exclusively for your brand using existing styles or semi-custom designs. You can add your brand logo and custom packaging.

White Label – The manufacturer sells pre-designed, ready-to-brand products that multiple retailers can relabel and sell under their own names. Ideal for low-volume or fast-launch businesses.

Each model serves different needs — OEM for creativity and control, Private Label for branding flexibility, and White Label for speed and affordability.

The Evolution of the Modern Puffer Vest Manufacturer

In the past, factories focused purely on production. Today, a professional Puffer Vest Manufacturer must also provide:

Design consultation

Material sourcing

Pattern development

Technical testing

Private label customization

Flexible MOQ

This evolution has blurred the lines between manufacturer and brand partner — and Ginwen stands at the forefront of this transformation.

Our OEM & Private Label clients include outdoor brands, urban fashion labels, and corporate distributors who value quality consistency and scalable production.

Why Brands Need to Understand the Difference

Understanding the difference between OEM, Private Label, and White Label models allows fashion businesses to:

1.Control costs effectively

2.Choose realistic MOQs

3.Protect brand integrity

4.Optimize development timelines

For example, a startup designer launching a capsule collection might prefer Private Label, while a large retailer looking to expand into outerwear might benefit from OEM development for exclusive fits.

Meanwhile, entrepreneurs testing a market can use White Label puffer vests to validate demand before committing to bulk orders.

Ginwen Expertise in All Three Models

At Ginwen, we don’t force clients into one model — we help them identify which manufacturing strategy best supports their growth.

Whether you’re a fashion startup needing quick turnaround or an established retailer with detailed tech packs, our flexible production systems make us a one-stop Puffer Vest Manufacturer.

OEM – Design-to-delivery customization with CAD prototyping.

Private Label – Ready styles, customizable branding, small MOQ.

White Label – Pre-approved classic vests for fast market entry.

We handle every stage — from fabric inspection, washing, and cutting to printing, sewing, and packaging — ensuring quality and reliability throughout.

OEM Manufacturing Model: Full Customization and Brand Control

What Is OEM Manufacturing?

The OEM (Original Equipment Manufacturer) model is the most comprehensive production method for brands seeking creative control and technical precision.

In this structure, the client provides detailed design concepts, tech packs, or samples, while the Puffer Vest Manufacturer handles the entire production — from sourcing materials to final packaging.

OEM is ideal for brands that:

Have unique designs or proprietary silhouettes

Require specific insulation types or performance features

Want full control over branding and quality

Need a long-term production partner

This model allows you to bring your design vision to life without operating your own factory — making it the preferred option for professional labels and wholesalers worldwide.

The OEM Workflow Explained

At Ginwen, we follow a structured and transparent process for OEM projects to ensure efficiency and precision.

Step 1: Design & Technical Consultation

We begin with a consultation to understand your concept, market positioning, and material preferences. Our in-house CAD team then creates digital patterns and virtual prototypes for your approval.

Step 2: Fabric Sourcing & Testing

We source performance fabrics such as recycled polyester, nylon, and water-repellent shell materials. Each batch undergoes inspection, washing, and hydrostatic pressure testing to ensure durability and waterproof performance.

Step 3: Sampling (7–14 Days)

Once materials are approved, we produce a pre-production sample to verify fit, construction, and finish. Clients can request adjustments to fine-tune their custom puffer vest before bulk production.

Step 4: Bulk Production (30 Days)

After sample confirmation, the order moves into our automated production system, capable of producing up to 500,000 pieces monthly.

Each process — cutting, quilting, sewing, and labeling — is managed under strict ISO 9001 quality controls.

Step 5: QC & Shipping

Before shipment, every vest undergoes real-time quality monitoring and a final inspection to ensure measurements, colors, and workmanship meet client expectations.

Why OEM Gives You Full Brand Control

Unlike White Label or Private Label models, OEM manufacturing gives you total ownership of design and brand identity.

You decide:

The materials and trims

The insulation type (down, feather, or synthetic fill)

Stitching and quilting patterns

Labeling, logos, and packaging

This ensures your custom puffer vest stands out in the market — not just another generic product.

For fashion brands, OEM is essential for maintaining exclusivity. For wholesalers, it ensures product differentiation and repeat business.

At Ginwen, our OEM clients include emerging designers, technical outerwear startups, and premium retailers who require made-to-spec quality backed by industrial scalability.

📍 Discover more about our OEM & ODM capabilities:

Technical Advantages of Working with a Professional OEM Puffer Vest Manufacturer

As an experienced OEM Puffer Vest Manufacturer, Ginwen integrates advanced technologies to support brand development:

1.CAD pattern-making & digital fitting simulation – guarantees accuracy and reduces sample revisions

2.Automated cutting & quilting systems – ensure precision stitching and insulation consistency

3.ISO 9001 & BSCI certified systems – guarantee ethical and traceable production

4.Private label customization – allows you to integrate your own branding seamlessly

5.Flexible MOQ (100 pieces) – suitable for both new collections and large seasonal drops

6.Lead time efficiency: samples in 7–14 days, bulk production in 30 days

By combining these capabilities, we make OEM production accessible to both small and large brands without sacrificing quality or delivery speed.

Case Example: OEM for a Technical Outerwear Brand

A European outdoor brand partnered with Ginwen to develop a line of lightweight puffer vests with RDS-certified down fill.

We collaborated closely on:

CAD pattern optimization for better mobility

Fabric testing for waterproof and windproof performance

Digital color matching for consistent branding

The result was a custom puffer vest collection that performed in harsh weather while maintaining premium aesthetics — now distributed in over 30 stores across Europe.

This demonstrates how the right Puffer Vest Manufacturer can turn technical requirements into tangible success stories.

When to Choose OEM

Choose OEM manufacturing if you:

Want to create a unique, high-quality collection

Have your own design team or clear specifications

Aim to scale internationally

Require professional testing, certification, and QC documentation

OEM is an investment in your brand’s long-term identity — and Ginwen ensures the process is smooth, transparent, and results-driven.

Private Label & White Label Manufacturing: Faster Routes to Market

Understanding Private Label Manufacturing

For many fashion brands and wholesalers, the Private Label model offers the perfect balance between customization, cost efficiency, and speed.

Unlike OEM manufacturing, where brands start from a blank page, Private Label allows businesses to select from a manufacturer’s existing styles and adapt them with their own branding and finishes.

This approach significantly reduces development time while maintaining brand ownership — making it ideal for companies looking to expand quickly or launch capsule collections.

A Private Label Puffer Vest Manufacturer provides semi-customized designs that can be adjusted in color, fabric, or trim, but the silhouette and structure remain based on proven templates.

How Private Label Works at Ginwen

At Ginwen, we make private label manufacturing simple and transparent.

As an experienced Puffer Vest Manufacturer, we maintain a library of base designs developed through years of pattern refinement and market feedback.

Our Process:

1.Style Selection – Clients browse our existing patterns and samples, choosing styles aligned with their audience.

2.Customization – We modify fabrics, insulation materials, and trims based on brand preference.

3.Branding & Labeling – We apply your private logo, care labels, hangtags, and packaging.

4.Sampling & Approval – A pre-production sample is sent for fit and aesthetic verification.

5.Bulk Production – Once confirmed, production begins under the same ISO 9001 & BSCI-certified workflow as our OEM projects.

This model allows brands to focus on marketing and sales while we handle the technical execution.

Advantages of Private Label Puffer Vest Manufacturing

Partnering with a Private Label Puffer Vest Manufacturer like Ginwen offers multiple strategic benefits:

Faster time-to-market – No need to design from scratch; pre-approved silhouettes accelerate production.

Cost efficiency – Lower R&D investment compared to OEM.

Brand exclusivity – Each design remains your property once customized.

Low MOQ (100 pieces) – Perfect for testing new collections or regional markets.

Premium quality assurance – We apply the same rigorous QC as OEM products.

This model is ideal for mid-size brands or wholesalers who need Custom Puffer Vests under their private labels without extensive design development.

White Label Manufacturing: The Quickest Market Entry

For startups or businesses aiming to launch products immediately, the White Label model is the fastest solution.

In this setup, the Puffer Vest Manufacturer sells ready-made, unbranded products that multiple clients can purchase and rebrand.

You simply select from existing designs, apply your own logo or packaging, and start selling — no design or sampling stages required.

White label manufacturing is especially effective for:

1.Online retailers and dropshipping businesses

2.Seasonal or promotional apparel campaigns

3.Early-stage brands testing new categories

How Ginwen Supports White Label Partnerships

We understand that speed and reliability are crucial for white label clients.

At Ginwen, our White Label Puffer Vest Supplier program includes:

1.Ready-to-ship classic vest designs in multiple colors and sizes

2.Optional private labeling service (woven labels, printed logos, packaging)

3.MOQ from 100 pcs per color or size mix

4.Consistent quality control using ISO 9001-certified systems

5.This enables our clients to reduce lead time while maintaining professional-grade product quality.

We ensure every Custom Puffer Vest — whether OEM, Private Label, or White Label — meets the same performance standards for insulation, stitching, and durability.

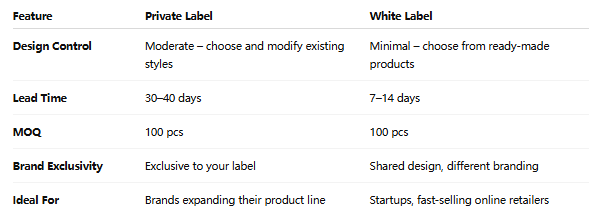

Choosing Between Private Label and White Label

In short:

Choose Private Label if you want flexibility with faster speed.

Choose White Label if you need the fastest, simplest route to market.

At Ginwen, we provide both — allowing clients to switch between models as their business grows.

📍 Browse our latest Private Label and White Label options:

Why Ginwen Excels in Both Models

We’ve optimized our production ecosystem to support different client needs simultaneously.

Our strengths include:

500,000 pcs monthly capacity with dedicated production lines

7–14 day sample turnaround / 30-day bulk shipment

Real-time production tracking for transparency

Flexible cooperation models – OEM, Private Label, or White Label

In-house CAD & QC teams to ensure fit accuracy and consistency

As your Puffer Vest Manufacturer, we adapt to your workflow — whether you’re a high-end brand, distributor, or fast-moving eCommerce label.

Why the Right Puffer Vest Manufacturer Defines Your Brand

Whether you’re an outdoor brand, fashion label, or wholesale distributor, partnering with the right Puffer Vest Manufacturer determines more than just product quality — it defines your brand identity, supply chain stability, and scalability.

In an industry where design trends shift fast and demand for sustainable, functional apparel grows stronger every year, having a reliable manufacturer who can deliver across OEM, Private Label, and White Label models gives you a lasting competitive advantage.

At Ginwen, we position ourselves not just as a supplier but as a strategic manufacturing partner for forward-thinking brands.

1. Certified & Ethical Manufacturing

Our production facility is both ISO 9001 & BSCI certified, ensuring every order meets international standards for quality management and social compliance.

This means our clients can confidently promote their Custom Puffer Vest collections as ethically made, sustainable, and performance-tested — a critical factor for modern consumers and global retailers.

✅ ISO 9001 Quality Management Certification

✅ BSCI Social Responsibility Certification

✅ OEKO-TEX® Certified Materials

✅ RDS-Certified Down Supply Chain

We don’t compromise on transparency or ethics — every vest we produce carries our commitment to responsibility and excellence.

2. End-to-End Production Strength

What makes Ginwen stand out as a Puffer Vest Manufacturer is our ability to manage every stage of production under one roof.

Our Full Manufacturing Scope Includes:

Fabric inspection, washing, and testing

CAD pattern-making and digital prototyping

Automated cutting, quilting, and sewing lines

Custom printing, embroidery, and labeling

Final QC, packaging, and export logistics

With a monthly production capacity of 500,000 pieces, we handle bulk wholesale orders while maintaining small-batch flexibility for capsule collections or sampling.

This combination of scale and precision allows us to meet tight deadlines while ensuring every custom puffer vest meets the highest quality standards.

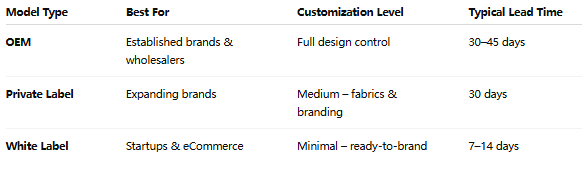

3. OEM, Private Label & White Label Expertise

We understand that every brand operates differently — which is why our team is trained to adapt our services to your model:

We understand that every brand operates differently — which is why our team is trained to adapt our services to your model:

Our clients can switch seamlessly between these models as they scale — maintaining consistency in product quality and communication.

4. Real-Time Quality & Process Control

We believe manufacturing transparency builds trust.

Through our internal real-time production monitoring system, clients receive consistent updates on sampling progress, order status, and QC milestones.

Every project is overseen by our in-house engineers and merchandisers, ensuring communication gaps never delay production.

Combined with our three-tier QC structure — pre-production, inline, and final inspection — Ginwen guarantees precision, durability, and comfort in every puffer vest we produce.

5. Flexibility that Empowers Growth

Our production setup is built to serve both emerging brands and global retailers:

1.MOQ: 100 pieces – accessible for startups and boutique collections

2.Sample turnaround: 7–14 days

3.Bulk completion: 30 days

4.Dedicated OEM/ODM consultation team

We know agility matters — especially when managing new product launches or replenishment cycles. That’s why our clients value our ability to adapt fast without compromising quality.

6. Why Global Brands Choose Ginwen

Our partners describe Ginwen as “a manufacturer that thinks like a brand.”

We understand fit, fabric, and fashion trends, not just production metrics.

Every collaboration begins with careful consultation and ends with a product that reflects both performance and aesthetic excellence.

Our Key Strengths at a Glance:

ISO 9001 & BSCI certified manufacturing systems

In-house CAD prototyping & pattern development

500,000 pcs monthly capacity

Automatic production process (fabric inspection, cutting, quilting, packaging)

Real-time production tracking and bottleneck management

Private label customization & OEM flexibility

7–14 days sampling / 30 days bulk shipment / MOQ 100 pcs

📍 Explore our full collection of styles here:

7. Conclusion: Partner with Ginwen for Your Next Collection

Choosing between OEM, Private Label, and White Label manufacturing isn’t just about production — it’s about shaping your brand’s long-term growth strategy.

At Ginwen, we provide all three models under one certified system, empowering you to start small, grow fast, and scale sustainably.

We’ve helped hundreds of fashion labels, outdoor brands, and wholesalers build reliable supply chains and successful private label collections.

Now, it your turn.

👉 Start your next project today:

Explore our Custom Puffer Vest Collection

Learn about our OEM & ODM Service

Get in touch via Contact Us — our specialists reply within 24 hours.

At Ginwen, your vision becomes a reality — one perfectly stitched puffer vest at a time.