The Ultimate Guide to Premium Custom Bomber Jacket Manufacturers

Introduction

In this comprehensive guide, we dive deep into everything you need to know about choosing the right bomber jacket manufacturers for your brand. From manufacturing certifications and in-house development capacity, to quality management systems and private-label services, we’ll cover the key criteria, industry best practices, and why working with a true partner like Ginwen is the smart choice. If you're seeking premium custom bomber jacket manufacturers who can support MOQ 100 pieces, fast turnaround, and OEM/ODM flexibility — read on to learn how to find and evaluate them, and why Ginwen stands out in the market.

Why Choosing the Right Bomber Jacket Manufacturer Matters

When your brand is looking to launch a collection of bomber jackets, partnering with the right bomber jacket manufacturers can make or break your success. These jackets are not just seasonal garments — they represent brand identity, quality, fit, and finishing. A poor manufacturing partner can lead to delays, inconsistent sizing, weak materials, or sub-par durability. On the other hand, the right manufacturer brings:

reliable production capacity;

consistent quality control;

the flexibility to support custom designs and small minimum orders;

manufacturing systems that meet international standards;

transparent communication and strong in-house development.

So, let’s review the key criteria you should evaluate in any potential partner, and then we’ll explain how our company, Ginwen, meets and exceeds these benchmarks.

Key Criteria for Premium Custom Bomber Jacket Manufacturers

Here are the must-have capabilities you should check when selecting among custom bomber jacket manufacturers:

Certified Manufacturing Systems

Top-tier bomber jacket manufacturers will hold certifications such as ISO 9001 for quality management, BSCI for social compliance, and other environmental or safety standards. These certifications demonstrate an established system of quality, auditability, and reliability.

Strong In-House Team for CAD Development & Prototyping

Look for manufacturers with their own CAD design, pattern making, prototyping, and sample development teams. This enables faster turnaround from concept to sample to bulk, and reduces miscommunication between your brand and the factory.

Large Manufacturing Capacity & Automated Process

For reliable delivery, a manufacturer must have sufficient capacity and workflow automation — ideally a monthly production capacity in the hundreds of thousands of pieces, with automated or semi-automated inspection, washing, cutting, printing, and packaging. Without this scale, delays become common.

Scope of Services: Cutting & Sewing & Private Label Solutions

The best custom bomber jacket manufacturers not only cut and sew, but also offer private label, full-package services, material sourcing, custom trims, and finishing. This allows your brand to go from design to finished branded product seamlessly.

Quality Management & Real-Time Production Monitoring

Quality control must be built in: in-line inspections, bottleneck identification, tracking of production progress, finishing checks, packaging, and shipment inspections. Manufacturers with real-time monitoring systems can proactively address issues before numbers run away.

Minimum Order Quantities (MOQ) and Lead Times

A flexible yet professional manufacturer will support reasonable minimums (for example, MOQ 100 pieces or similar), sample turnaround in 7-14 days, and bulk production completion in around 30 days. These metrics are important for small brands or seasonal launches.

Transparency, Sustainability & Brand Partnership

Finally, the ideal manufacturer will align with your brand’s values: transparency in sourcing, sustainability, eco-friendly materials, traceable supply chains, and a partnership mentality (not just a supplier-vendor). This is increasingly critical for premium brands.

How Ginwen Meets These Criteria (and More)

Here at our company — Ginwen — we pride ourselves on being one of the most capable and reliable custom bomber jacket manufacturers in the industry. Let me introduce our brand and how we deliver on the criteria above:

OEM & ODM Services

Who We Are

We at Ginwen are a trusted OEM & ODM outerwear manufacturer with 20+ years of experience in apparel production, based in China and serving global fashion brands, sportswear labels, and lifestyle companies.

Our focus includes puffer jackets, down jackets, bomber jackets, varsity jackets, and other custom apparel.

Our Manufacturing Capabilities

We operate an ISO 9001 & BSCI certified manufacturing system.

Our monthly production capacity reaches 500,000 pieces, and our process includes automatic inspection of fabrics, automated cutting, printing, washing, and packaging.

We support sample production in 7-14 days, and the bulk order lead time is around 30 days.

We provide cutting & sewing services plus private label solutions, enabling your brand to turn a design into reality.

We have robust real-time monitoring of production progress and bottlenecks, ensuring quality is proactively managed at every stage.

(This detailed technical capability reinforces why Ginwen stands out among other bomber jacket manufacturers.)

Custom Bomber Jacket Expertise

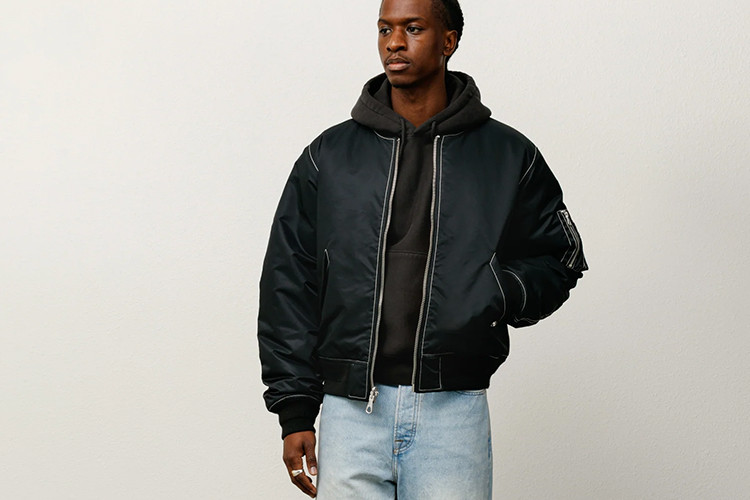

Our flagship custom bomber jacket collection can be found here: Custom Bomber Jacket Collection

Through this collection, you can explore sample styles, finish options, trimming variations, and brand-friendly customization layouts.

OEM & ODM Services

Whether you have a design in mind or need us to co-develop one with you, we offer full OEM & ODM services. Visit our OEM/ODM service page: OEM & ODM Service

We’ll support your brand from fabric sourcing, CAD design, prototyping, finishing, packaging, and shipment.

Brand-Focused Partnership & Sustainability

At Ginwen, we don’t just manufacture — we partner with brands. We focus on eco-conscious materials, reducing waste in production, supporting small-batch runs (our MOQ of 100 pieces makes small brands accessible), and ensuring efficient, ethical manufacturing.

Why Choose Ginwen as One of Your Bomber Jacket Manufacturers

Flexibility & Access: MOQ of 100 pieces helps new or niche brands scale.

Speed to Market: Rapid sampling in 7-14 days, bulk completion in ~30 days.

Dedicated Expertise: Years of experience in outerwear and bomber jackets specifically.

End-to-End Services: From concept to finished garment (private label, custom trims, packaging).

Transparent & Sustainable: Production systems that meet high standards; you can trust that your brand image is preserved.

Global Export Experience: We serve Europe and North American markets extensively.

If you’re ready to inquire or start a quote, visit our Contact Us page: Contact Ginwen

How to Select & Evaluate Potential Bomber Jacket Manufacturers

Here are practical steps you can follow when evaluating custom bomber jacket manufacturers for your brand:

Check Certifications & Factory Audit

Ask for copies of ISO 9001, BSCI, or equivalent factory audits. Visit (virtually or in person) the production line. A manufacturer with lean systems, defined production flow, and documented quality checks will stand out.

Review Sample Work & Portfolio

Request sample bomber jackets from previous clients (or your own mock-up). Evaluate fit, finishing, trim quality, stitching consistency, material behavior after washes. A manufacturer focused on “just sewing” will lack advanced finishing.

Inspect In-House Development and Sample Lead Time

How long does it take to make a sample? Do they have their own CAD, pattern-making, and prototyping? If manufacturing relies heavily on outsourcing design, lead time and quality may suffer.

Assess Production Capacity & Equipment

For consistent brands, you cannot rely on a tiny workshop. Ask about monthly capacity (for example, 500,000 pieces), automation level (fabric inspection machines, automatic cutters, printing/embroidery equipment). This is what separates premium bomber jacket manufacturers from lower-tier ones.

Understand the Scope of Services

Does the manufacturer only do cut & sew, or do they provide trims, custom branding, packaging, and logistics? Full-service manufacturers let you focus on your brand and marketing while they handle manufacturing minutiae.

Examine Quality Management & Monitoring

A good manufacturer will show you production monitoring dashboards, inspect fabric roll defects, monitor bottlenecks, and sample QC before shipping. Ask for their QC process and metrics.

Review MOQ, Lead Times & Flexibility

For custom bomber jackets, you may be working with seasonal launches or limited runs. Good manufacturers support minimum orders of 100 pieces and a sample lead time of around 7–14 days, with bulk production around 30 days. If a manufacturer demands huge MOQ and long lead times, you may face trouble launching.

Sustainability & Brand Integrity

If your brand emphasises ethical manufacturing, confirm the manufacturer uses eco-friendly materials, a traceable supply chain (GRS, OEKO-TEX, RDS), less waste, and transparent reporting. Premium bomber jacket manufacturers will be able to deliver not just a garment, but a story aligned with your brand values.

Payment Terms & After-Sales Support

Check payment structure, shipment arrangements, and buffer for defects/returns. A trustworthy manufacturer will have clear policies and responsive support throughout.

The Manufacturing Workflow for Custom Bomber Jackets

Understanding the workflow helps you manage expectations and timelines while working with bomber jacket manufacturers:

Design & Concept Development

Brand provides a mood board, tech-pack, or design sketch.

The manufacturer's CAD and development team translates into patterns and specs.

Sample trims and materials discussed and approved.

Sampling & Prototyping

Initial sample built (7-14 days typical).

Fit test, material behavior test, finishing test.

Adjustments made, sign-off for bulk production.

Pre-Production & Material Sourcing

Fabric inspection (automatic or manual) for defects.

Trims and accessories sourced (zippers, linings, labels, hang tags).

Cut planning and lay-up for efficient fabric use.

Bulk Production

Fabric cutting (automated if available).

Sewing and assembly (cut & sew).

Washing/finishing if required (for garment-washed bomber jackets).

Printing/embroidery/trims added.

Quality checks at key milestones (inline inspection, final inspection).

Packing into private-label boxes, hang tags, and branded packaging.

Final Inspection & Shipping

100% final QC or sample checks.

Shipment arranged via agreed logistics (air, sea).

Post-shipment support for any defects or returns.

Post-Production Review & Feedback Loop

Brand and manufacturer review performance (fit issues, returns, consumer feedback).

Improvements fed into the next production cycle.

This workflow applies when you partner with premium custom bomber jacket manufacturers. Having a partner who actively manages each step ensures speed, quality, and brand coherence.

Common Challenges When Working with Bomber Jacket Manufacturers (and How to Avoid Them)

Even when working with experienced manufacturing partners, brands can face pitfalls. Here are typical challenges and how to proactively handle them:

Material & Trim Delays

Bomber jackets often use special fabrics, linings, wool/nylon blends, custom zippers, or patches. If sourcing is delayed, bulk production lags. Mitigation: agree on lead times for trims, keep substitute options, and early approval of prototypes.

Fit & Proportion Issues

Because bomber jackets have a distinct silhouette (rib knit, waistband, collar, epaulet, etc.), small pattern errors become visible. Mitigation: insist on a detailed tech-pack, a checkpoint for fitting, and pre-bulk size set sampling.

Finishing & Consistency

Wholesale runs must maintain uniform finishing (wash, color, sewing tension). Lower-quality factories may lack proper finishing lines or QC systems. Mitigation: select manufacturers with automated inspection, and request pre-shipment photos or video.

Lead Time Overruns

With multiple components, the production schedule can slip. Mitigation: build a buffer into your launch plan, choose a partner with strong capacity (e.g., monthly capacity 500,000 pieces), and ask for real-time production monitoring.

MOQ Too High or Inflexible

Small or emerging brands may struggle to find bomber jacket manufacturers who support low minimums. Mitigation: Specifically ask for MOQ 100 pieces if you are launching or testing, and choose a partner who supports that.

Brand and Manufacturing Misalignment

If the manufacturer is purely commodity-focused, brand identity and finishing may get diluted. Mitigation: choose a partner that offers private label services, robust in-house design capability, and emphasizes quality and brand collaboration — like Ginwen.

How to Prepare Your Brand Before Engaging Bomber Jacket Manufacturers

To get the best result from your collaboration with custom bomber jacket manufacturers, your brand should come prepared:

Prepare a detailed tech-pack: sketches, dimensions, material/construction details, trims/labels, packaging.

Decide your MOQ, budget, and launch time frame. For example: sample in 7-14 days, bulk in ~30 days.

Define your brand identity: will it be streetwear bomber jackets, luxury fabric bomber jackets, or seasonal colors?

Choose your materials and trims: rib knits, zippers, lining, and embroidery patches.

Establish your quality expectations and communicate clearly.

Have your logistics and packaging requirements ready: branded hang tags, care labels, branded poly bags, or boxes.

Request the manufacturer’s capacity, lead times, and sample policy.

Confirm after-sales support and warranty policies: what happens if you find defects post-shipment?

Being aligned on these details helps you and the manufacturer stay on the same page and reduces costly revisions.

Real-World Example: Launching a Custom Bomber Jacket Line with Ginwen

Let’s walk through how a brand might work with us — Ginwen — as their chosen bomber jacket manufacturer:

Initial Inquiry & Design Brief

You contact us with your concept, desired style (e.g., varsity-style bomber, streetwear satin bomber, wool blend bomber), and your launch plan.

We review your requirements, check MOQ (100 pieces), sample timeline (7-14 days), and bulk production timeline (~30 days).

Development & Sample

Our in-house CAD and pattern-making team translates your design into a prototype.

We source materials and trims, and produce the sample within 7-14 days.

You review the sample: fit, quality, finishing, appearance.

Bulk Production

Upon sample approval, production begins. We handle fabric inspection, automated cutting, sewing and finishing.

Our monthly capacity of 500,000 pieces ensures we meet your schedule.

We monitor production in real-time, manage bottlenecks, and ensure quality via our QC team.

Branding & Packaging

We apply your private label, hang tags, and branded packaging as per your specifications.

Final inspection is completed, and goods are prepared for shipment.

Shipping & Post-Launch Support

Ship your bomber jackets to your distribution or warehouse.

We follow up on any issues with returns or quality feedback and feed improvements into your next production run.

By choosing Ginwen, you’re choosing a manufacturer that understands bomber jackets, delivers premium quality and treats your brand as a partner — not just another order.

Frequently Asked Questions (FAQ) about Bomber Jacket Manufacturers

Q1. What is a typical MOQ for custom bomber jackets?

A1. For premium custom bomber jacket manufacturers, MOQ can range from 100 to 500 pieces per colour/style. At Ginwe,n we support MOQ from 100 pieces, making it accessible for new and growing brands.

Q2. How long does it take from design to shipment?

A2. A typical timeline: Sample development: 7-14 days. Bulk production: ~30 days. Including shipping, you should anticipate 5–8 weeks total. (Ginwen offers this kind of turnaround.)

Q3. What certifications should I look for in a manufacturer?

A3. Look for ISO 9001 for quality management, BSCI (or Sedex) for social compliance, and environmental certifications (e.g., GRS, OEKO-TEX) if your brand emphasises sustainability. Premium bomber jacket manufacturers will have these in place.

Q4. How can I ensure consistent quality across colours and batches?

A4. Choose manufacturers with automated inspection, fabric roll defect detection, inline sewing QC, and final pre-shipment inspection. Ensure that the manufacturer provides documentation and photographs of each batch. Ginwen has such systems built in.

Q5. What services fall under OEM vs ODM when it comes to bomber jackets?

A5. OEM: You supply the design, brand, specifications, and the manufacturer produces accordingly. ODM: The manufacturer helps develop the style, offers design suggestions, materials, and trims, and you brand the final product. Ginwen offers both OEM & ODM services: OEM & ODM Service

Q6. How does sustainability factor into selecting a bomber jacket manufacturer?

A6. Sustainability includes eco-friendly materials, reduced waste, a traceable supply chain, and ethical labour practices. Manufacturers who can source sustainable fabrics, hold relevant certifications, and provide transparent reporting add value for premium brands. Ginwen emphasises this kind of responsible production.

Final Thoughts & How to Move Forward

If you are in the market for premium custom bomber jacket manufacturers, you now know what to look for: certified systems, strong in-house development, large capacity, full scope of services, quality monitoring, flexible MOQ/lead times, and brand alignment.

At Ginwen, we deliver all of this — and more. With 20+ years of industry experience, specialization in outerwear and bomber jackets, full OEM/ODM capability, sample turnaround in 7-14 days, bulk production around 30 days, and support for MOQ 100 pieces, we are a top choice for brands seeking a strategic manufacturing partner.

To start your next project:

Visit our Custom Bomber Jacket Collection: Custom Bomber Jacket

Learn about our OEM/ODM services: OEM & ODM Service

Contact us to request a quote or discuss your design: Contact Us

With the right partner, your bomber jacket line can achieve premium quality, strong brand identity, and reliable delivery — connecting you with your target audience and building brand loyalty.

Thank you for reading this guide to premium custom bomber jacket manufacturers. We look forward to the opportunity of working together and helping your brand succeed.

Understanding the Global Landscape of Bomber Jacket Manufacturers

The bomber jacket is one of the most iconic outerwear pieces in modern fashion. From its military origins to its adaptation into high fashion and streetwear, the demand for bomber jacket manufacturers capable of merging heritage and innovation has skyrocketed.

When choosing a manufacturer, you’re not just selecting a factory — you’re selecting a strategic production partner who understands both design aesthetics and industrial efficiency. Global manufacturing regions like China, Vietnam, and Bangladesh all have strengths, but Chinese factories — particularly ISO 9001 & BSCI certified ones like Ginwen — combine large-scale automation, quality craftsmanship, and flexibility, making them the preferred choice for fashion brands worldwide.

The Anatomy of a Perfect Bomber Jacket

Before collaborating with custom bomber jacket manufacturers, it’s essential to understand what makes a premium bomber jacket exceptional. Each element of its construction influences the final fit, comfort, and perceived brand quality.

Fabric Selection

The foundation of every bomber jacket lies in its fabric. Popular choices include:

Nylon and Polyester: Lightweight, durable, water-resistant — perfect for sporty or casual looks.

Twill or Cotton Blends: Offer a refined, classic touch for premium lines.

Wool or Wool-Blend Fabrics: Ideal for luxury winter bombers.

Recycled and Eco Fabrics: Increasingly preferred by sustainable brands and available through manufacturers like Ginwen, who integrate eco-conscious sourcing.

Lining and Insulation

Lining defines comfort and performance. Many bomber jacket manufacturers offer customizable linings such as breathable mesh, satin, or quilted insulation. Ginwen provides advanced lining customization — from lightweight poly taffeta to recycled polyester padding — depending on your brand’s needs.

Zippers, Ribs, and Finishing

The detailing defines the premium feel. Metal zippers (YKK, SBS), rib-knit collars, cuffs, and waistbands, as well as embroidery or silicone badges, give bomber jackets their personality. Premium custom bomber jacket manufacturers integrate branded trims and hardware, which Ginwen can help design through its OEM development services.

Stitching and Fit

Precision stitching ensures durability. Our engineers at Ginwen use automated cutting and stitching machines, reducing variance and ensuring consistent quality across all 500,000 pieces produced monthly.

Sustainability Trends Among Modern Bomber Jacket Manufacturers

Sustainability has become a core requirement for modern brands — and thus a defining feature of the best bomber jacket manufacturers. Brands are seeking partners who can provide eco materials, ethical production, and traceable sourcing.

Eco Materials

Sustainable bomber jackets may use recycled nylon, organic cotton, or plant-based padding (like Sorona®). Ginwen actively sources such materials for clients who wish to align with environmental commitments.

Waste Reduction

Advanced CAD systems reduce cutting waste. Ginwen’s in-house CAD prototyping optimizes fabric layout, reducing waste and improving efficiency — an advantage many smaller factories cannot provide.

Ethical Labor & Compliance

Manufacturers with BSCI certification guarantee ethical work environments. Ginwen’s production facilities meet BSCI standards and undergo annual audits to maintain transparency and accountability.

Responsible Packaging

From recycled cartons to biodegradable polybags, responsible packaging matters. Ginwen supports clients by offering eco packaging options, enhancing brand storytelling for sustainability-focused labels.

Why Small and Mid-Sized Brands Choose Ginwen

Many small to mid-sized fashion labels face difficulty finding manufacturers that accept smaller orders without compromising quality. At Ginwen, we bridge this gap.

Flexible MOQ

With an MOQ of only 100 pieces, we make premium production accessible to new and emerging labels. You can test designs, launch capsule collections, or introduce limited editions without overstock risk.

Speed & Efficiency

We understand that time-to-market determines brand competitiveness. That’s why we maintain a 7–14-day sample window and 30-day bulk lead time, ensuring your collection hits retail schedules or online drops efficiently.

Dedicated Support

Each client at Ginwen gets personalized project management — from sample coordination to shipping updates. Our English-speaking team bridges cultural and logistical gaps, making collaboration seamless.

Trusted by Global Brands

For over two decades, Ginwen has supplied premium outerwear to European and North American fashion brands. Our reputation for reliability and consistent craftsmanship has made us one of the most trusted bomber jacket manufacturers in the region.

OEM vs ODM: Which Works Best for Your Brand?

When selecting bomber jacket manufacturers, you’ll encounter two collaboration models — OEM and ODM.

OEM (Original Equipment Manufacturing)

In this model, you supply your design, tech pack, and specifications. The manufacturer produces according to your instructions. This approach suits established brands with defined collections.

ODM (Original Design Manufacturing)

Here, the manufacturer provides design assistance or ready-developed models that you can brand. It’s ideal for brands seeking guidance or those entering new product categories.

At Ginwen, we provide both options through our OEM & ODM Service page, allowing flexibility for both creative startups and established labels.

The Value of Transparency in the Manufacturing Process

Transparency is not just a buzzword — it’s an operational standard at Ginwen. We offer clients full visibility over their order progress:

Fabric Inspection Reports (before cutting begins)

Photo and Video Updates during sewing and finishing

Real-Time Progress Charts to monitor bottlenecks

Final QC Documentation before shipping

These systems reinforce trust — a cornerstone of long-term relationships between brands and premium bomber jacket manufacturers.

Advanced Technologies in Modern Bomber Jacket Production

Technology drives efficiency and precision in modern outerwear manufacturing. Leading custom bomber jacket manufacturers integrate innovations such as:

Automatic Fabric Spreading & Cutting Machines — ensuring accuracy and minimizing waste.

3D CAD Simulation — enabling visual fit analysis before physical sampling.

Digital Printing & Laser Embroidery — adding customization and brand uniqueness.

RFID Tracking Systems — offering real-time production tracking.

Heat-Sealed or Bonded Seams — for performance or weatherproof bomber jackets.

Ginwen's automated production lines include CAD-controlled cutting tables, auto fabric washing, printing, and digital embroidery systems — a combination rarely found in mid-scale manufacturers.

Private Label Opportunities with Ginwen

Private label manufacturing empowers brands to sell under their own label without investing in production infrastructure.

Ginwen provides private label bomber jacket manufacturing services that include:

Customized embroidery or print logos

Woven labels, size tags, and branded trims

Custom packaging (boxes, hangtags, polybags)

Fabric and color selection support

Barcode and logistics coordination

Our private label program helps small to medium-sized fashion labels grow efficiently while maintaining full brand ownership. Explore more on our Custom Bomber Jacket Collection Page.

Case Study: From Concept to Collection

Client: European streetwear brand launching a capsule bomber jacket series.

Goal: 300 units across three colors, with embroidered logo and satin lining.

Phase 1: Development

Ginwen’s CAD team digitized the design and generated prototypes within 10 days.

Phase 2: Sampling

Fabric and trim options were reviewed online; samples delivered in 12 days.

Phase 3: Production

Upon approval, Ginwen executed full-scale production — 300 jackets completed within 28 days.

Phase 4: Delivery

Order shipped via air freight, complete with private-label packaging and inspection documents.

Outcome: The client successfully launched on time, achieving a sell-through rate of over 90% within the first month.

This case exemplifies how custom bomber jacket manufacturers like Ginwen deliver both speed and quality for global fashion startups.

How to Request a Quote or Sample from Ginwen

Getting started is simple:

Visit our Custom Bomber Jacket Collection Page

Fill out the inquiry form or share your tech pack.

Our development team will review and confirm the sample cost, MOQ (100 pieces), and delivery time (7–14 days).

After sample approval, you’ll receive a detailed quotation with a 30-day production schedule.

Confirm your order, and we handle the rest — from fabric sourcing to shipment.

For direct support, reach out via our Contact Us page — our international sales team is ready to assist.

Common Mistakes to Avoid When Working with Manufacturers

Not Defining Quality Parameters — Always establish thread count, zipper brand, fabric grade, and finishing expectations.

Skipping Fit Samples — Fit testing ensures consistency before mass production.

Ignoring Packaging Requirements — Packaging impacts the final brand impression.

Late Material Approvals — Delayed sign-offs can stall the schedule.

Underestimating Lead Times — Plan buffer weeks for logistics and customs.

By proactively addressing these, brands can save time, reduce errors, and strengthen collaboration with bomber jacket manufacturers.

Future of Bomber Jacket Manufacturing

The future of bomber jacket production is defined by technology, sustainability, and personalization:

3D Virtual Sampling will reduce waste and cost.

Smart Fabrics with temperature regulation will emerge.

AI-based Quality Control will improve precision.

Custom-On-Demand Manufacturing will enable micro-batch production with zero inventory.

At Ginwen, we are already integrating CAD digital sampling and eco padding options — ensuring we stay ahead as one of the leading custom bomber jacket manufacturers in China.

Conclusion — Partner with Ginwen for Premium Bomber Jackets

manufacturers — what defines quality, how to evaluate partners, and how to streamline production.

At Ginwen, we combine:

ISO 9001 & BSCI certified production systems

500,000 pcs monthly capacity with automated processes

7–14 day sample development and 30-day bulk lead times

MOQ from 100 pieces

OEM/ODM flexibility

Private label customization and sustainable materials

Real-time quality monitoring and global logistics support

If your brand seeks a reliable manufacturing partner who can turn your bomber jacket vision into reality, we’re here to help.

Visit:

Visit:

Let’s create your next standout collection — together with Ginwen, your trusted partner in premium bomber jacket manufacturing.