Waterproof Fabrics 101 for Custom Jacket: EVA, PU, PVC, Nylon & Polyester Compared

Introduction: Why Fabric Choice Defines Every Custom Waterproof Jacket

When it comes to creating a Custom Waterproof Jacket, the choice of fabric is the single most important factor that determines performance, durability, comfort, and style. Brands today demand waterproof outerwear that not only protects from rain and wind but also reflects their unique design identity. For wholesalers and fashion labels looking for OEM or ODM solutions, understanding the differences between waterproof fabrics such as EVA, PU, PVC, Nylon, and Polyester is critical before moving forward with production.

At Ginwen, we’ve specialized in manufacturing Custom Waterproof Jackets for over 20 years. As an ISO 9001 & BSCI certified factory, we combine high-volume capability with low MOQ flexibility, allowing our partners to start from just 1 piece for sampling or capsule collections. Our monthly production capacity exceeds 500,000 units, supported by advanced CAD prototyping, automated sewing lines, and real-time quality control. Whether you are a start-up brand or an established retailer, we ensure that your waterproof jackets meet both performance expectations and your creative vision.

EVA (Ethylene Vinyl Acetate): Lightweight and Eco-Friendly

EVA is one of the most widely used materials in entry-level waterproof apparel. Known for its lightweight structure, flexibility, and non-toxic properties, EVA is often chosen for rain ponchos, disposable raincoats, or promotional outerwear.

Advantages of EVA in Custom Waterproof Jackets

Eco-friendly: EVA is chlorine-free and considered safer for both wearers and the environment compared to PVC.

Lightweight & flexible: Perfect for jackets that need to be packable or ultra-light.

Cost-effective: A good solution for budget-conscious brands or mass giveaways.

Disadvantages of EVA

Limited durability: EVA is prone to tearing and has lower abrasion resistance compared to PU or Nylon.

Basic look: EVA often lacks the premium aesthetic that fashion brands require.

Breathability issues: While water-resistant, it can feel clammy during extended wear.

For brands that want to create low-cost promotional waterproof jackets, EVA is a practical material. But for premium outdoor jackets where durability and style matter, we often recommend higher-grade fabrics.

PU (Polyurethane): The Balance of Style and Waterproofing

PU-coated fabrics are one of the most popular choices in today’s fashion and outdoor industries. Polyurethane can be applied as a coating over fabrics like polyester or cotton, creating a waterproof yet breathable layer.

Advantages of PU in Custom Waterproof Jackets

Durability with flexibility: PU coatings make jackets waterproof while maintaining fabric softness.

Versatile finish: Brands can choose from matte, glossy, or leather-like finishes, making PU ideal for fashion-forward waterproof jackets.

Breathability: PU-coated fabrics allow better airflow than PVC, making them more comfortable for extended wear.

Custom branding potential: Easy to integrate with private label services, logos, and trims.

Disadvantages of PU

Moderate lifespan: PU coatings can degrade with time, especially in high humidity.

Higher cost vs EVA: More durable but requires a slightly higher investment.

Care needs: Jackets need proper storage to prevent peeling or cracking of the coating.

At Ginwen, we often recommend PU-coated fabrics for brands that want to strike a balance between style, waterproofing, and comfort. Our in-house CAD and cutting teams can prototype PU-based Custom Waterproof Jackets within 7–14 days for samples, ensuring your design ideas are tested before scaling to bulk production.

PVC (Polyvinyl Chloride): Heavy-Duty Waterproofing

PVC is one of the most recognized materials in the waterproof apparel industry, especially for industrial-grade waterproof jackets. With its naturally waterproof and windproof qualities, PVC provides a 100% barrier against rain, snow, and harsh weather.

Advantages of PVC in Custom Waterproof Jackets

Absolute waterproofing: PVC creates a strong impermeable layer, making it perfect for jackets used in heavy rain or industrial workwear.

Durability: Resistant to tearing, abrasion, and harsh environments.

Cost-effective for bulk orders: Affordable in large-scale manufacturing.

Easy to clean: Jackets made from PVC can be wiped clean, making them ideal for outdoor workers.

Disadvantages of PVC

Heavyweight: PVC jackets can feel bulky and restrict movement.

Poor breathability: Traps heat and moisture inside, making them uncomfortable for long wear.

Environmental concerns: Contains chlorine and is less eco-friendly compared to EVA or PU.

At Ginwen, we manufacture Custom Waterproof Jackets for industrial and workwear clients who require rugged PVC protection. However, for fashion and lifestyle brands, we often recommend nylon or polyester blends to balance comfort and style.

Nylon: The Premium Choice for Performance Jackets

Nylon is considered the gold standard for many premium outdoor Custom Waterproof Jackets. Known for its high tensile strength, abrasion resistance, and flexibility, nylon has become a top choice for sportswear, hiking gear, and technical outerwear.

Advantages of Nylon

Durability: Outperforms polyester in strength and abrasion resistance.

Lightweight yet strong: Perfect for jackets that must be both portable and tough.

Versatility: Works well with advanced coatings like PU, TPU, or DWR (durable water repellent).

Fashion appeal: Smooth surface allows brands to achieve a polished, high-end look.

Disadvantages of Nylon

Higher cost: Nylon is more expensive than polyester.

Water absorption: Without coatings, nylon tends to absorb water and dry slowly.

UV sensitivity: Prolonged sun exposure can cause fading or degradation.

For brands seeking performance-driven waterproof jackets, nylon is often the best material. At Ginwen, our CAD development team helps fashion labels and outdoor brands design nylon-based waterproof jackets with additional features like seam sealing, breathable linings, and down filling for thermal insulation.

Polyester: The Affordable All-Rounder

Polyester is one of the most widely used fabrics in Custom Waterproof Jacket manufacturing. It is less expensive than nylon but offers excellent performance when combined with coatings like PU or PVC.

Advantages of Polyester

Cost-effective: A budget-friendly option for brands producing large collections.

Quick-drying: Unlike nylon, polyester does not absorb much water, making it more suitable for rainy environments.

Color retention: Resistant to fading, ideal for fashion-forward collections.

Versatile: Works with multiple coatings and laminations for waterproofing.

Disadvantages of Polyester

Lower strength: Weaker than nylon in terms of abrasion resistance.

Less premium: Lacks the high-end aesthetic of nylon-based jackets.

Breathability limits: Requires additional design elements to enhance comfort.

Polyester is often the go-to for brands that want a balance between affordability and waterproofing. At Ginwen, we’ve supported wholesalers and retailers in developing polyester-based Custom Waterproof Jackets that integrate sustainable coatings, recycled polyester blends, and private label branding options.

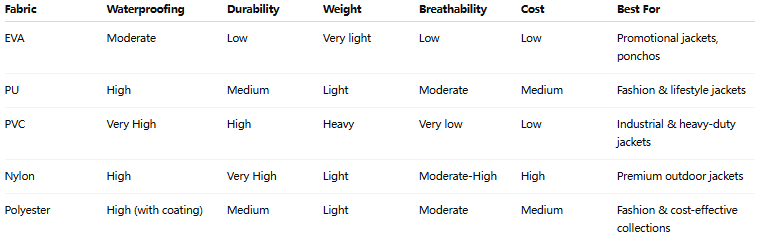

Comparative Analysis: EVA, PU, PVC, Nylon & Polyester

To help brands decide, here a simplified comparison:

This table illustrates how Custom Waterproof Jacket performance depends not just on material but also on coatings, design, and manufacturing expertise. That why working with an experienced partner like Ginwen ensures you get the right balance of cost, performance, and brand positioning.

Ginwen – Your Trusted Partner in Custom Waterproof Jackets

At Ginwen, we specialize in designing and producing Custom Waterproof Jackets for brands, retailers, and wholesalers worldwide. With more than 20 years of manufacturing expertise, we have become a reliable partner for labels that demand both high performance and design flexibility.

What sets us apart is our ability to support both startups and large-scale brands. Whether you need a single prototype to test a new design idea, or a bulk production run of 50,000+ pieces, we can meet your needs efficiently. Our MOQ starts from just 1 piece, making us one of the most flexible factories in the waterproof outerwear industry.

Why Choose Ginwen for Your Custom Waterproof Jacket Project

ISO 9001 & BSCI certified manufacturing systems – ensuring ethical, standardized, and sustainable production.

In-house CAD development & prototyping – from fabric inspection to digital design, we bring your concepts to life.

Large-scale manufacturing capacity – up to 500,000 pieces per month, powered by automated production lines.

Full-scope services – including cutting, sewing, washing, printing, packaging, and private label branding.

Real-time quality control – we monitor bottlenecks and production progress to ensure timely delivery.

Fast turnaround – samples ready in 7–14 days, bulk production completed in about 30 days.

By combining technical precision with creative flexibility, we help brands launch waterproof outerwear collections that stand out in a competitive market.

OEM & ODM Services Tailored for Brands and Retailers

As an OEM & ODM manufacturer, Ginwen provides end-to-end solutions for your waterproof apparel projects:

OEM (Original Equipment Manufacturing): Send us your tech packs or design drafts, and our in-house team will translate them into professional patterns and final products.

ODM (Original Design Manufacturing): Choose from our catalog of Custom Waterproof Jackets, and we can adapt styles with your brand’s trims, logos, and packaging.

Our services are designed for:

Start-up fashion brands that need low MOQ flexibility.

Outdoor retailers requiring high-performance jackets with down filling or thermal insulation.

Private label wholesalers seeking fast, large-scale production capacity.

👉 Learn more about our OEM & ODM Service.

Real-World Applications of Custom Waterproof Jackets

The versatility of Custom Waterproof Jackets means they can be tailored for multiple market segments:

Outdoor & Adventure Brands – Nylon-based waterproof jackets with breathable membranes and seam-sealed construction.

Urban Lifestyle Collections – PU-coated polyester jackets with sleek designs for city wear.

Workwear & Industrial Use – Heavy-duty PVC jackets offering maximum protection.

Sustainable Fashion Labels – Recycled polyester or eco-friendly EVA for green collections.

At Ginwen, we don just produce jackets — we provide solutions aligned with your brand positioning and market goals.

Building Long-Term Partnerships

We understand that choosing a manufacturer is not just about fabrics — it about building trust. By offering transparent timelines, professional communication, and consistent quality, we aim to become a long-term manufacturing partner for your brand.

Our clients include both emerging fashion labels and well-known international retailers. Each collaboration starts with a simple conversation and a clear plan.

👉 Reach out today via our Contact Us page and let discuss your next Custom Waterproof Jacket project.

Conclusion: Choosing the Right Fabric and the Right Partner

When comparing EVA, PU, PVC, Nylon, and Polyester, it becomes clear that no single fabric is perfect for every jacket. EVA is lightweight and eco-friendly, PU balances style and function, PVC excels in durability, nylon dominates in premium performance, and polyester delivers cost-effectiveness.

But the true success of a Custom Waterproof Jacket lies in choosing not just the right fabric, but also the right manufacturing partner. At Ginwen, we combine technical expertise with flexible production models to help brands launch waterproof jackets that meet their performance, sustainability, and fashion goals.

Whether you need a single prototype within 14 days or a bulk order of 30,000 jackets delivered in one month, we’re ready to deliver. With ISO-certified systems, strong in-house R&D, and large-scale automated production, Ginwen stands as your reliable partner in Custom Waterproof Jackets.